Architectural Details: Foster + Partners’ Sculptural Metal Ceiling

Find the perfect ceiling panels for your next project through Architizer’s new community marketplace for building-products. Manufacturers: Check out the latest construction leads and sign up now.

Search for Metal Cladding Manufacturers ➭

The Bloomberg Headquarters in London is the new nerve center of Bloomberg’s European operations and is widely considered “the most sustainable office building in the world.” Compared to a conventional office, the Bloomberg building consumes 73% less potable water, 35% less energy and produces 300 fewer tons of carbon emissions per year. In fact, when completed in 2017, it scored an outstanding 98.5% under BREEAM — the international equivalent of the LEED green building rating system — setting a record as the highest score ever achieved by a major office development.

The exterior of Bloomberg HQ in London; photo by Nigel Young.

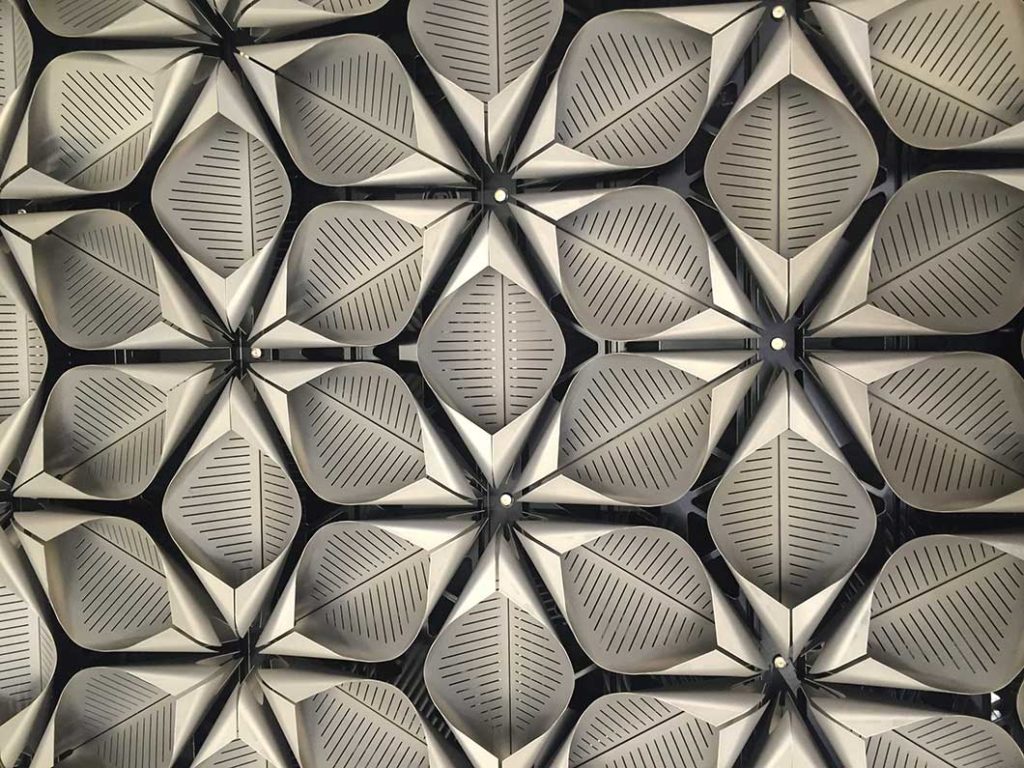

The building’s impressive environmental performance is made possible by several smart mechanical systems that cogenerate heat and renewable power, recycle rainwater to serve low-flow toilets, and automatically regulate natural ventilation based on occupancy levels. The most innovative feature, however, are the integrated ceiling panels found throughout the interior which are composed of millions of bespoke aluminum petals. “Without [these ceilings] the sustainability wouldn’t be what it is,” said Michael Jones, project architect for Foster + Partners.

The interior ceilings feature 2.5 million bespoke aluminum petals; photo by Nigel Young.

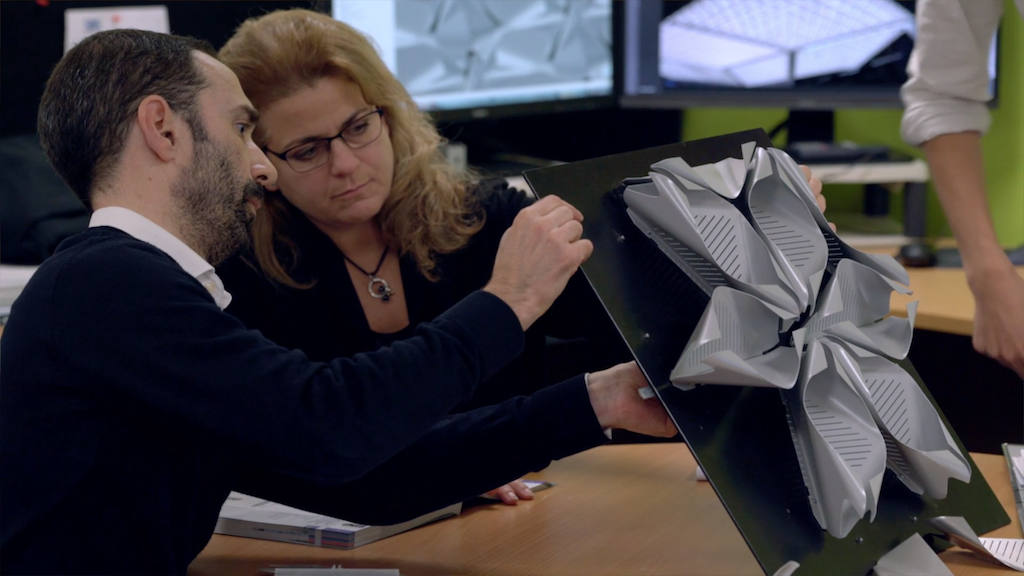

The ceiling panels were developed in partnership with SAS International, a local firm that has collaborated with the architects on a number of projects in the past but none of which rival Bloomberg in terms of scale or complexity. Each panel combines highly efficient lighting, thermal and acoustic controls together into what Richard Wright, Design Director for SAS International, believes to be “the first fully integrated ceiling panel in the United Kingdom, if not the world.”

The panels are fabricated from 75% recycled aluminum; photo via SAS International.

There is a total of 3,916 panels installed within the building, clad in approximately 2.5 million petals. In order to fabricate this staggering number of petals without drastically increasing the building’s carbon footprint, the team specified Hydro R75 rolled aluminum, a product which is guaranteed to contain a minimum of 75% post-consumer recycled content and up to 25% recycled scrap aluminum from industrial processes.

The petals were modeled using CFD software to maximize thermal performance; screenshot via SAS International.

Aluminum is a highly conductive metal, making it the perfect choice for an integrated cooling system. During the summer, the aluminum petals are chilled by water pipes concealed behind the panels. As air from the ventilation system passes through the slotted petals, it is rapidly cooled, providing a low-energy alternative to traditional air conditioning. The shape of the petals was modeled using Computational Fluid Dynamics (CFD) software to maximize their surface area while optimizing air flow.

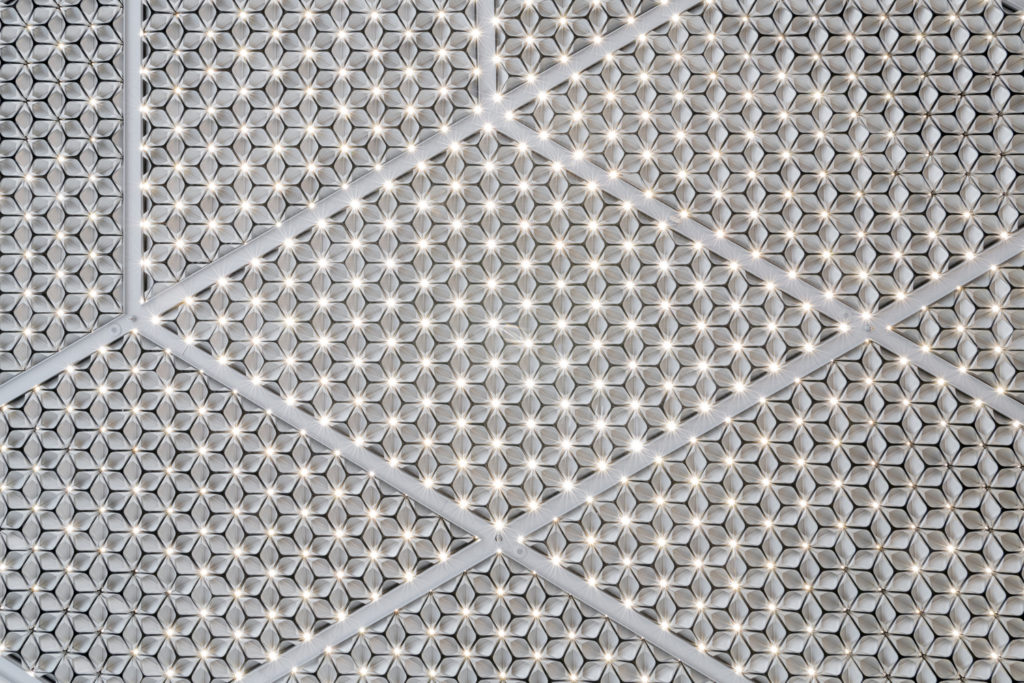

The interior is illuminated by 450,000 soft white LEDs; photo by Nigel Young.

The ceiling panels also provide the interior illumination. They are equipped with 450,000 LED downlights, supplied by Luxonic, which burn 40% less electricity than typical office lighting systems. Since LEDs perform best when kept cool, integrating these fixtures into the chilled panels significantly improves their energy efficiency and overall life expectancy. Additionally, the reflectivity of the petals helps diffuse light more evenly throughout the interior while their three-dimensional shape shields eyes from glare.

The panels are perforated to achieve a Class A acoustic performance rating; photo via SAS International.

Although aluminum is wonderful for transferring heat and reflecting light, it is not ideal for interior acoustics because it can cause reverberation, especially in open-plan offices. To counteract this, the project team spaced the petals apart slightly and riveted them to a perforated metal substructure. As sound passes through these openings, it is absorbed by an internal layer of mineral wool insulation, resulting in a Class A acoustic performance rating.

The ceiling took 38,000 collective hours of design work to perfect; photo via SAS International.

The panels are rhomboidal rather than square, further complicating the design process. This necessitated the development of a custom ‘click-lock’ profile for their edges so that they could be mass produced and easily installed into an angled support structure. Incorporating the various mechanical systems into a mass produced module was an immense undertaking which required 38,000 collective hours of design work, as well as input from lighting specialists, acoustic consultants and HVAC technicians.

The final ceiling is the result of a precise choreography between these various disciplines. “The whole ceiling system and the layout was designed to give us accurate dimensions,” explained White, “The CAD information was then taken and used to produce 3D models which the factory used to produce all of the components. Everything was on a massive scale … When you look at Bloomberg and you realize there is something like 12,000 individual parts incorporated into the project, the logistics of that are phenomenally complex.”

Search for Metal Cladding Manufacturers ➭

Search for the best ceiling panels through Architizer’s new community marketplace for building-products. Click here to sign up now. Are you a ceiling panel manufacturer looking to connect with architects? Click here.

The post Architectural Details: Foster + Partners’ Sculptural Metal Ceiling appeared first on Journal.

, Jon Cornachio, read more Journal http://bit.ly/2JQUVcv

Yorumlar

Yorum Gönder