How Architects Can Adapt for Our Climate Crisis

Resilient design has emerged as a paradigm shift in architectural practice. Increasingly covered by the AEC industry over the last two decades, the need for adaptation, mitigation and regulatory strategies has become irrefutable as climate change has been identified as one of the 21st century’s biggest global crises. On average, the destruction caused by extreme weather events has cost the U.S. economy $200 billion a year over the past 10 years. Recognizing escalating climate concerns and understanding that the nature of weather events is unlikely to remain the same throughout a building’s life span, architects are now looking for tools, products and innovative building assemblies to manage risk and build resilience.

The American Institute of Architects released a statement saying that “scientific consensus shows increasing atmospheric levels of carbon dioxide contribute significantly to rising sea levels, extreme weather events and degradation of natural resources. These trends threaten national security, human health, food supply, natural ecosystems and global economies.” Closely tied to operational and embodied carbon production in buildings, architects and manufacturers are now focusing on sustainable and integrated specs.

In this article, we look at how to specify details and products that address increased temperatures, reduce emissions, and store up both water and energy. Passive solutions to mitigate temperature center on thermal mass, insulation, external shading and cross ventilation. These adaptive systems come in the form of green roofs, cooling technologies, low heat producing light and equipment as well as co-generation methods like photovoltaic glazing and waste heat capture technology. The following exemplars in resilient design explore these systems through details, building-products and novel specifications.

The Hotchkiss School, Biomass Heating Facility by Centerbrook Architects & Planners, Salisbury, Conn., United States

The new Central Heating Facility for The Hotchkiss School in Lakeville, Connecticut was made to reduce greenhouse gas emissions. This resilient design features an undulating sloped green roof that’s vegetated with sedum connected with a bio-swale rain garden.

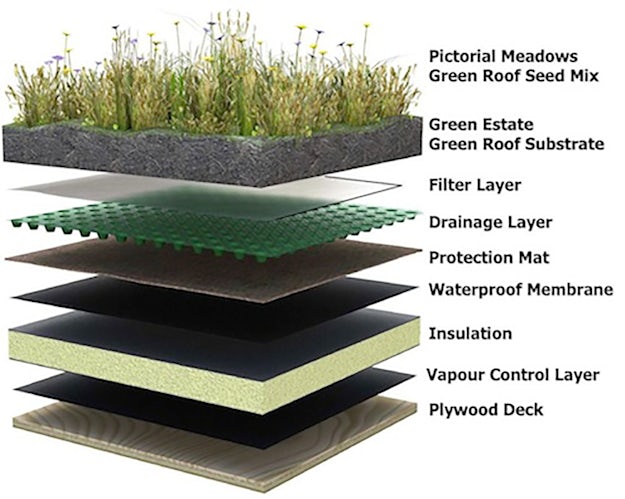

The treatment center’s green roof captures 50% of the site’s rainwater with precultivated sedum mats laid directly onto the green roof substrate. The sedum carpet green roof system was provided by ZinCo USA on top of a Sika Sarnafil waterproofing membrane. When specifying green roofs like this, it’s important to choose a strong and durable waterproof membrane beneath the soil. The following diagram shows some of these layers that make up a green roof system:

In the Hotchkiss School, a protection mat was placed on top of the waterproofing membrane to protect the roof during installation and to retain water for the roof in times of extended drought. They used a Floradrain FD25-E drainage layer to ensure proper drainage while retaining a specific amount of water for the roof’s vegetation.

Research Green Roof Manufacturers

Bullitt Center by The Miller Hull Partnership, Seattle, Wash., United States

The Bullitt Center is the first leasable market rate commercial structure to target requirements for the Living Building Challenge. A landmark building in Seattle, the design was created to inform future high-performance urban buildings.

Designed to achieve net-zero energy use with 100% on-site renewable energy, the center gained attention for its potentially illegal systems. As mentioned in one of our previous articles, in Washington, filtering rain water for drinking wasn’t allowed. The Bullitt Center was therefore designed to use its treated rainwater for graywater until future changes to the law.

The building’s performance is boosted by mechanized features like automated retractable blinds to block glare and heat gain, as well as windows that automatically open and close to optimize natural ventilation. Essentially its own power plant and its own waste treatment plant, the project integrated systems for power production, daylighting, heating, cooling and ventilation.

Geothermal wells combine with hydronic radiant tubing, commonly called PEX, that coils a few inches beneath the concrete overlay of each floor. This, alongside 575 PV manufactured by the Sunpower Corporation of San Jose, are only a few of the products and systems that create a truly resilient design.

Research Photovoltaic Manufacturers

Stamp House by Charles Wright Architects, Queensland, Australia

The Stamp House project was designed as an off-grid residence on the edge of a rainforest. Embracing the surrounding native wetland environment, the house rests above an engineered water ecosystem through a combination of in-situ and precast concrete. The carbon-neutral design features a 250,000-liter rainwater harvesting system, renewable solar energy generation, an on-site sewage treatment plant, a controllable building automation system, as well as shaded and insulated thermal mass engineering.

Built as a collaboration process between Queensland’s national parks, environmental agencies, and state and local governments, the Stamp House was made to withstand the region’s frequent cyclone activity and minimally impact its environment. Featuring a solid structure, the sustainable building makes use of huge cantilevers to diminish the threat from potential flooding and tides.

Research Concrete Manufacturers

Find more materials for resilient design on Architizer’s community marketplace for building-products. Click here for more information on the best all-in-one specification platform for architects.

The post How Architects Can Adapt for Our Climate Crisis appeared first on Journal.

, Eric Baldwin, read more Journal http://bit.ly/2OGQ3tv

Yorumlar

Yorum Gönder